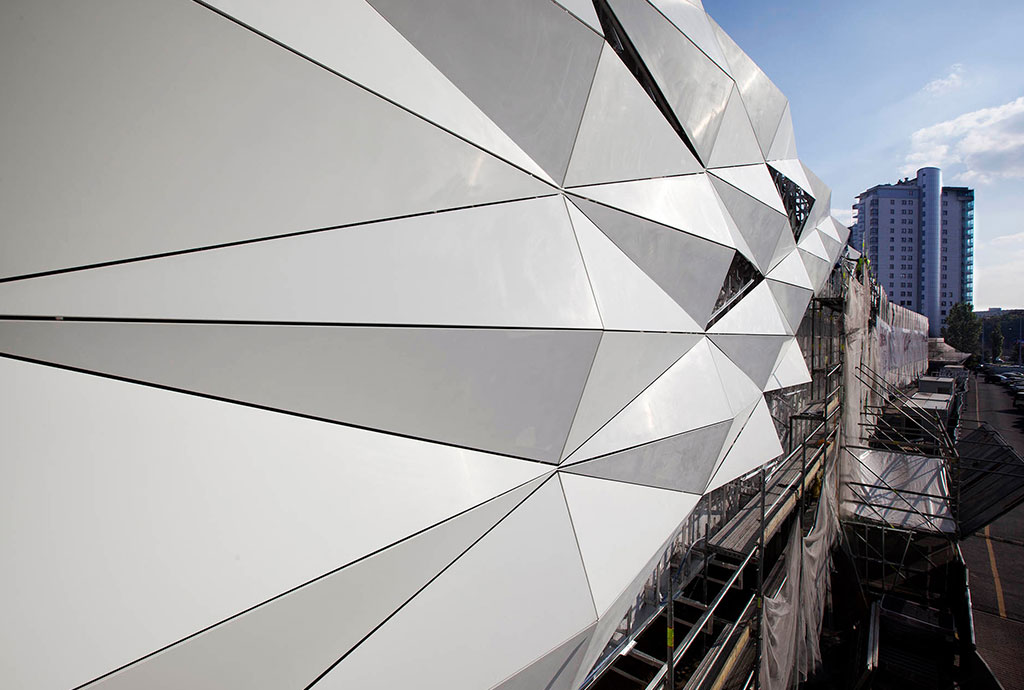

Klif Shopping Centre

Diamond sparkles on the façade of Warsaw Klif Shopping Center

The Warsaw Dom Mody Klif shopping centre has gained an impressive and elegant setting, a new face and a new personality at the end of 2012. Architect bureau ‘Grupa 5 Architekci’ revolutionized the building conceiving a ventilated façade adopting DuPont™ Corian® high-tech surface to conceive – first in Poland – an advanced solution in architectural techniques.

The completed project of the facade – whose shape recalls diamonds – was selected in a closed competition organised by the owner of the shopping centre – PAIGE Investments Sp. z o.o. Dom Mody Klif was opened in 1999 and is one of the first such facilities built in the capital of Poland. A similar shopping centre was opened in Gdynia a few years earlier in 1996.

The original Klif shopping centre building in Warsaw had been designed by architect Thomas Kozlowski who wanted to give it a look of the piano. It has changed its character over the years in parallel with the modifications of customers’ tastes. Recently the Klif Warsaw incorporated also cafes, travel agencies, restaurants, clothing stores and other commercial premises, a change that added an elegance to the overall environment.

After a few years of functioning the investors wanted to make the building more comfortable and friendly: changes were made outside and inside of the building to create fresh, modern and original spaces for visitors and lessees. Lighting and ceiling were redesigned, a resting area was built and a ventilation system revamped. Interiors were designed by Marek Tryzybowicz with a team of architects from Bose International Planing and Architecture. The most distinguished and visible change is the re-designed facade of the Klif, conceived by Grupa 5 Architekci.

Its aim was to create exclusivity and uniqueness to the building. The main architect Rafal Grzelewski comments “Our goal was to propose a new garment that would make Klif an icon of architecture. Material DuPont™ Corian® fulfilled idea of the project and hi aesthetic expectations. The fact that it is a first building with a facade made in surfacing material hi tech DuPont™ Corian® was another challenge.” About 1700 square meters of DuPont™ Corian® have been used for the facade of the building.

In 2012, DuPont™ Corian® achieved a positive result after an exhaustive testing program made by Building Research Institute (Instytut Techniki Budowlanej) and verified that the material meets all the Polish building requirements for exterior cladding materials and applications.

This modern surfacing material from DuPont™ also met all the specifications and requirements set for the Klif project. It was important that it is resistant to UV radiation and easy to renovate. Its non-porous surface also provides that, after many years of heavy use, the material still looks fresh and elegant.

“The building is opened to the Okopowa street so the length of the facade and building proportions were significant design guidelines. Arrangement and distribution of panels refers to the shape of diamonds which will be underlined by illuminated glass panels scattered throughout the facade. Entrances are highlighted by black lining. Facade is complemented by landscaping project: specially designed for this project paving, pergolas, strings pedestrians and small architecture” describes Rafal Grzelewski, Gropa 5 Architekci.

T.I.K.O. Systemy company was chosen to fabricate the façade. The company developed modular components that allow to assemble not only simple façade planes, but also complex three-dimensional structures. The challenge in this project was to measure precisely all inequalities on elevation of the walls and arches, which, after the elimination of breakdowns gave regular and spatial form. It was important also to take into account the thermal expansion of the surface of DuPont™ Corian® and the preservation of angles and distances between the panels.

The key task was to make specially designed tables and mould cavities so it is easy to cut and get the panels ready to be installed on the façade. Properly prepared mould cavities allowed to keep repeatability of linear and angular sizes for each format. Each two triangles were cut from the 1300 x 3658mm panel except the quoin where the sizes were different and accustomed to the angle of the building.

Rafał Grzelewski, Groupa 5 Architekci, says “We took under consideration exposition and different weather conditions and designed a ventilated facade. The spacing between the panels was used for this purpose.

Advanced surfacing material DuPont™ Corian® is smooth, so any kind of dirt is deposited less heavily on its surface than other materials. In addition, the cleaning is very simple and basic. Mounted at different angles, panels create beautiful shadows in both natural and artificial light.

Artur Ziółko, T.I.K.O. Systemy, says “A key task that we set ourselves was to design and build special tables for cutting and shaping DuPont™ Corian® panels. None of the triangles put on the facade had right angles. We made different moulds in order to maintain the repeatability of linear and angular dimensions. With the use of professional equipment for cutting, handling and dust extraction – further work was not a problem.” He adds: “As an executive company that was making first in our country facade of DuPont™ Corian® we had to do a lot of internal studies, projects and tests in order to verify our decisions. Today we have knowledge and experience in this field and we know how to perform the external facades of DuPont™ Corian® to meet the needs of developers and investors.”

Other Projects

Watsons Bay House

This residence, nestled in the Watsons Bay Heritage Conservation Area, embodies a harmonious blend of traditional aesthetics and contemporary design principles. Its structure, a three-level house, pays homage to the architectural heritage of the area’s original fishing village cottages. Yet, it diverges into modernity with its innovative use of space, materials, and integration with its […]

Ahead of the Curve – La Casa Curvilínea

La Casa Curvilínea is truly ahead of the curve with its minimal, modern interpretation of Mediterranean design by the visionary duo, Tyson and Teegan Doherty of Doherty Building Group. This beautiful four-bedroom family home is a symphony of gentle curves, warm hues, and innovative materials. At the heart of this serene abode lies its kitchen […]

Robina Town Centre Amenities

The i2C Interiors Team was engaged by QIC to re-imagine the amenities with a particular focus on the parent’s room at Robina Town Centre. Understanding the importance of amenities as a key customer touch point, QIC’s brief to i2C was to create a design that was better representative of the Robina Brand and more focused […]

The Avenue

When it comes to home renovations, it’s not just about the visual appeal but also about functionality, durability, and most importantly, the lifestyle it supports. Situated on the south coast, “The Avenue” is a prime example of how a full home renovation can be seamlessly blended with design and practicality. Taking inspiration from its coastal […]

Central Park Tower, Perth

The new Central Park Cafe, Hemingway, was designed in conjunction with the Central Park Lobby upgrade. The curved monolithic forms of the main lobby extended to the new cafe counter, with a large boulder-esque sculpted appearance, gently resting in place. The design team designed a cafe counter to look like a large boulder and were […]

Ora Apartments

Nestled along the beachfront of Sorrento WA, Ora Apartments stands as a testament to the pinnacle of coastal living. This exquisite residential haven, crafted by the esteemed architects and visionary interior design teams of MJA Studio, introduces you to the epitome of “barefoot luxury.” Among the many highlights is the Corian® Rain Cloud kitchen island, […]

Waterman Eastland

Waterman Eastland launches an innovative post-pandemic co-working model: a vibrant community within a retail, hospitality and services hub. Inspired by neighbouring Mullum Mullum Creek, it addresses WFH isolation and long commutes and connects diverse tenants via flexible offices, communal habitats and spectacular natural light and volumes from the adjacent atrium. Seamlessly woven into an existing […]

Chic Centrefold

New Zealand designer Annika Rowson has just unveiled this elegant beauty – a third kitchen in her Rowson Kitchens showroom. Having a showroom that changes every couple of years enables Annika not only to showcase leading edge materials, concepts and functional features in kitchen design, but also to personally challenge herself to apply materials in […]

The Aesthetic Mastery of TAEGA Cosmetic Clinic

Designed by the talented duo Yew Hann Loo (Hann) and Elly Yang of Axe Architects, TAEGA Cosmetic Clinic has successfully redefined the conventional cosmetic clinic experience, blending aesthetics and functionality seamlessly. The interior design, a meticulous creation by Hann and Elly, revolves around subtle colours, lighting, and textures, with a predominant light beige hue symbolising […]

Toorak House: Blending Mid-Century Charm with Contemporary Elegance

Nestled in the scenic lanes of Toorak, stands a mid-century gem that has witnessed the laughter and memories of two family generations. As times change and aesthetics evolve, homes too require a touch of modernity, and that’s exactly what Melanie Beynon Architecture and Design set out to do with the Toorak House. Melanie and the […]

Microsoft, North Sydney

Located within 1 Denison Street in North Sydney, the new Microsoft Australia Head Office breaks the mould of a traditional workplace and is a fully immersive experience. Thanks to the collective expertise of the GroupGSA team. Microsoft’s hybrid office experience features intelligent lighting, robotics and advanced workplace occupancy sensors linked to Microsoft platforms. The 10,000sqm […]

Beach View Residence: A Luxurious Day Spa Retreat Transformed

Birdblack Design, led by designer Stuart Gibson, has successfully transformed a standard bathroom into a breathtaking day spa retreat in the Beach View Residence. The project, which aimed to create a beautiful haven for the empty-nester clients, involved combining the main bathroom and WC to create one large, seamless space. Birdblack Design drew inspiration from […]

McDonald’s Sydney International Airport

Floating above the departing passengers, and announcing itself from afar, is a glowing yellow glass box; a new McDonald’s at Sydney Airport’s Terminal 1, designed by Landini Associates in collaboration with McDonald’s Australia. The brief for the restaurant was simple: create an iconic, memorable customer experience, like nothing seen before in restaurant design. For Landini, […]

Seamless Precision | Footscray Apartment

The owners of the apartment pictured desired a more ambiguous kitchen than usual. The functional facilities were conceived by Boardgrove Architects, as sculptural art-like objects rather than utilitarian pieces of equipment. Corian® was the natural choice for this project, as it is less stereotypical a material for kitchen benchtops in comparison the standard materials such as […]

Geoff Handbury Science and Technology Hub

The new Geoff Handbury Science and Technology Hub at Melbourne Grammar School, is a simple, singular sculptural structure. It produces compelling imagery that alludes to the scientific and technological investigations taking place within. The building is sympathetic to the campus heritage and identity, contributing to the ‘Bluestone Campus’ character in both form and colour. It […]

Mossman Court

The brief from the client was to design, build and install custom Joinery for a prestigious home in one of the most sought-after addresses in Noosa, Mossman Court. Corian® was used throughout the project, including Kitchen benchtops with moulded sinks, BBQ benchtop, Powder Room vanity with moulded basin, and various bathrooms and ensuites throughout the home, […]

Rhodes House, West Perth

The team at Cameron Chisholm Nicol worked closely with the client to design a personalised office space on Level 3, a café, additional office tenancies, amenities, and a basement EOT facility. The design of the Interior is bold in colour but minimalistic in form with sculptural Corian® elements that anchor the meeting/social spaces. The client […]

Ethereal Marine: A Modern Design Fusion

Designing a living space that perfectly encapsulates a client’s passions and preferences can be a challenging yet rewarding endeavour. In this case, Georgia Langridge from Modi Design took on the task of creating a kitchen and living space for a client who had two distinct loves: marine biology and rimu timber. Instead of shying away […]

FY Smile

Anna Trefely and the team at Esoteriko sought to interpret a landscape within a clinical context for this dental practice. Sanctuary-like, and ‘minty fresh’, deeply influenced by a Japanese-flavoured aesthetic where human experience, nature and technology are combined. It hints at a natural world which has undergone a process of distillation and reinterpretation. Multiple opportunities […]

Black Rock House

This site is perched on one of the highest topographical locations along Beach Road. The brief was to design a house with strong connections to the bay in order to remind the owners of their passion for boating and enjoyment of cruise ship holidays. The building form is an island surrounded by open ‘green’ space. […]

Lovey Patisserie

The brief was unique, a palette dominated by white and pink that gives off a sleek & modern vibe. What made this an interesting project was to incorporate retail sections that features collectable items such as Bear Bricks, Takashi Murakami’s pop art, KAWS figurative vinyl toys and many more. The intention was to create an […]

Swanbourne Beach Residence

This beachside residence boasts uninterrupted coastal views from the kitchen. With this in mind, Humphrey Homes wanted to create beautiful natural hues throughout the kitchen and house to complement the natural environment on the home’s doorstep. Corian® Witch Hazel gave these lovely sandy, earthy hues to the kitchen. It worked with the natural textural palette […]

Wantirna Residential Aged Care

The Wantirna Aged Care Facility is a 120-bed development designed to improve resident privacy, dignity and independence whilst delivering best-practice care in a home-like environment. The facility supports a range of resident care needs and contemporary models of care to provide a dementia-friendly environment. The design aims to optimise physical and mental wellbeing through access […]

Coledale

Based in the Illawarra, Rachael Miklas Design and Detail is a trusted local interior design studio specialising in new construction and renovations in the local area. Rachael was entrusted with the design for Coledale, a new build right on the waterfront. The home lends itself to light and breezy atmosphere, where simplicity and cleverly thought […]

Seamless Style and Functionality: The Influence of Corian in Fostering Collaboration at Datacom’s Canberra Office

Nestled in the heart of Canberra, the Datacom office showcases a thoughtful approach to workplace design. Crafted by the creative minds at Leffler Simes Architects, this office space is geared towards promoting seamless communication and collaboration among colleagues. One key element in bringing this vision to life is the use of Corian, a versatile and […]

High School Laboratory Benches

Traditional materials for school laboratory surfaces seem to be taking a back seat as Corian®, comes to the forefront. Originally known for kitchen and bathroom applications, Corian® holds a robust appeal in the demanding environment of school laboratories. Three key attributes define Corian® as an ideal choice: durability, a non-porous nature, and simple maintenance. Not […]

The H2 Home Project Blends Contemporary Design with Seamless Curves and Tranquil Aesthetics

Rust Architecture Design, a leading design firm, has unveiled their latest masterpiece, the H2 Home project, situated on the stunning waterfront of Southeast Queensland. This contemporary two-level residence was meticulously crafted to embrace the region’s climate, capturing abundant daylight, refreshing breezes, and creating a serene sanctuary for its inhabitants. With a focus on livability and […]

Blending Nostalgia and Nutrition: Meet the Whimsical World of RAMBUTAN

The RAMBUTAN fruit studio, designed by the innovative Yaroslav Galant, is more than just a place to buy fresh produce; it’s an experience that marries the nostalgia of yesteryear with the contemporary love for wellness. The vintage style of RAMBUTAN sets the stage for a captivating club atmosphere, creating a haven for those who appreciate […]

Island Retreat

This island getaway renovation project blends practical high-end materials with sophisticated organic design techniques and the latest technologies to create an elegantly timeless and serene weekend escape for the client. The overall design brief for the project was to creatively transform the existing beach house into a very open and subdued glamorous island retreat that […]